What is Kapasitematik?

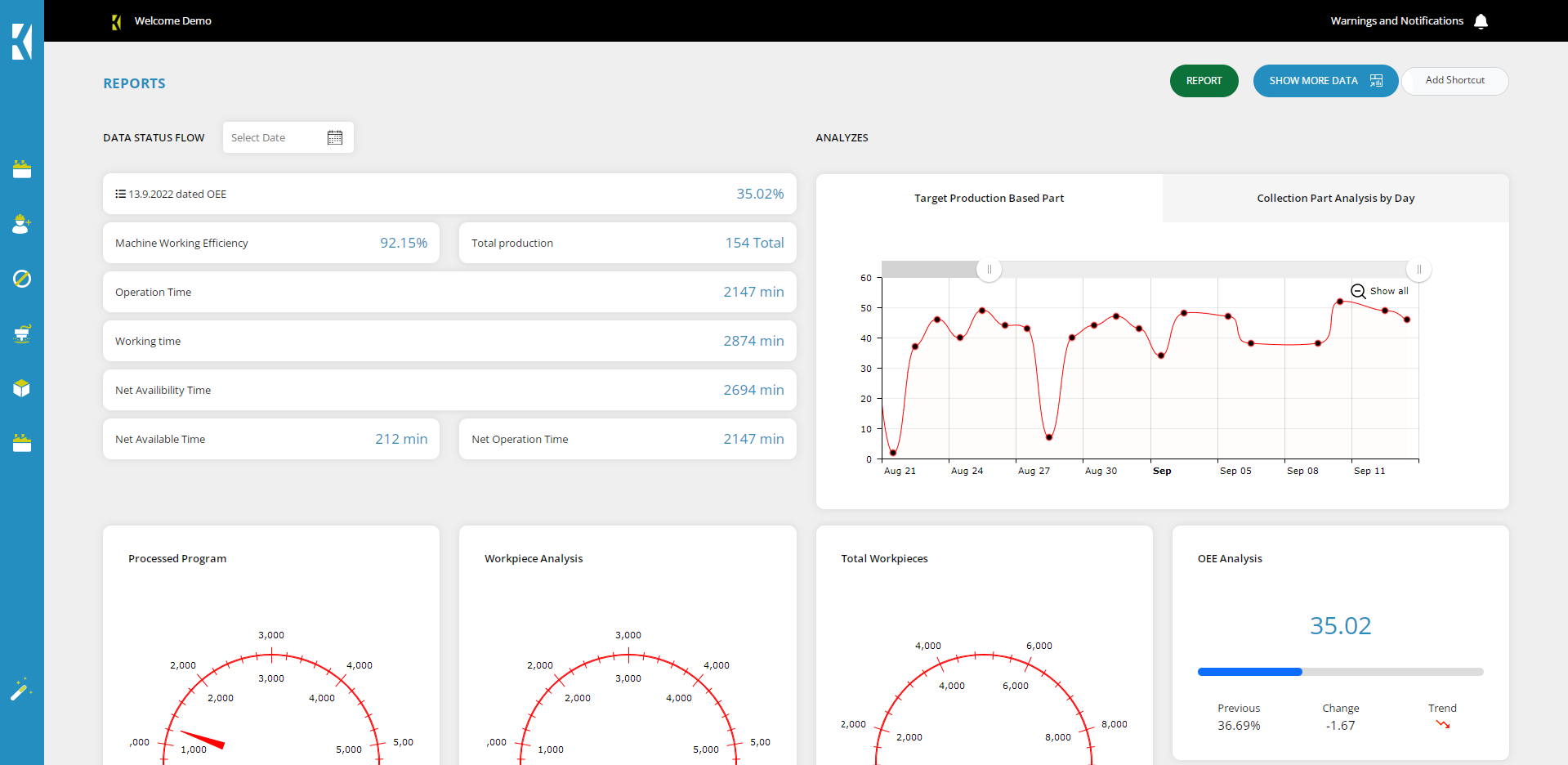

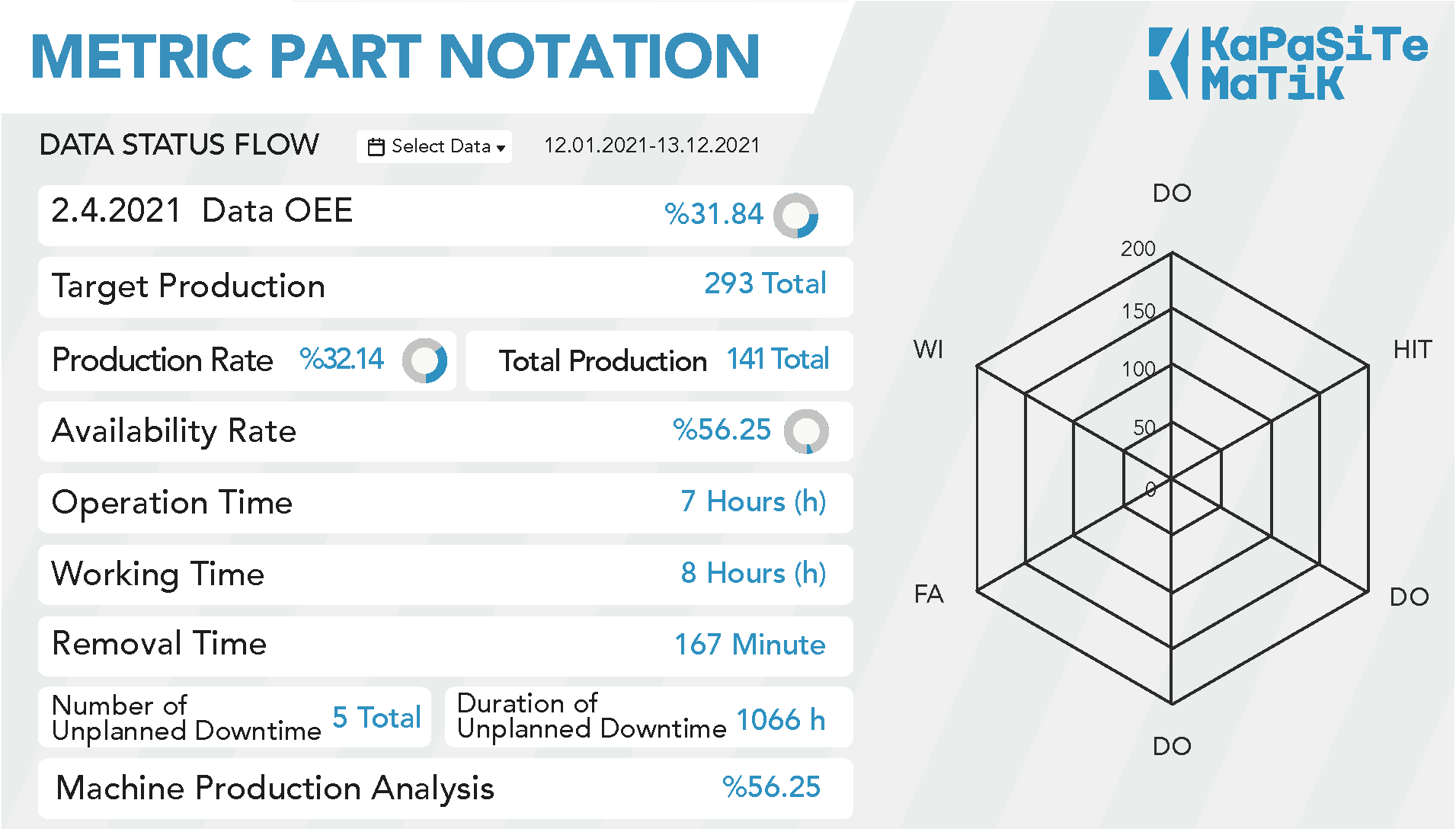

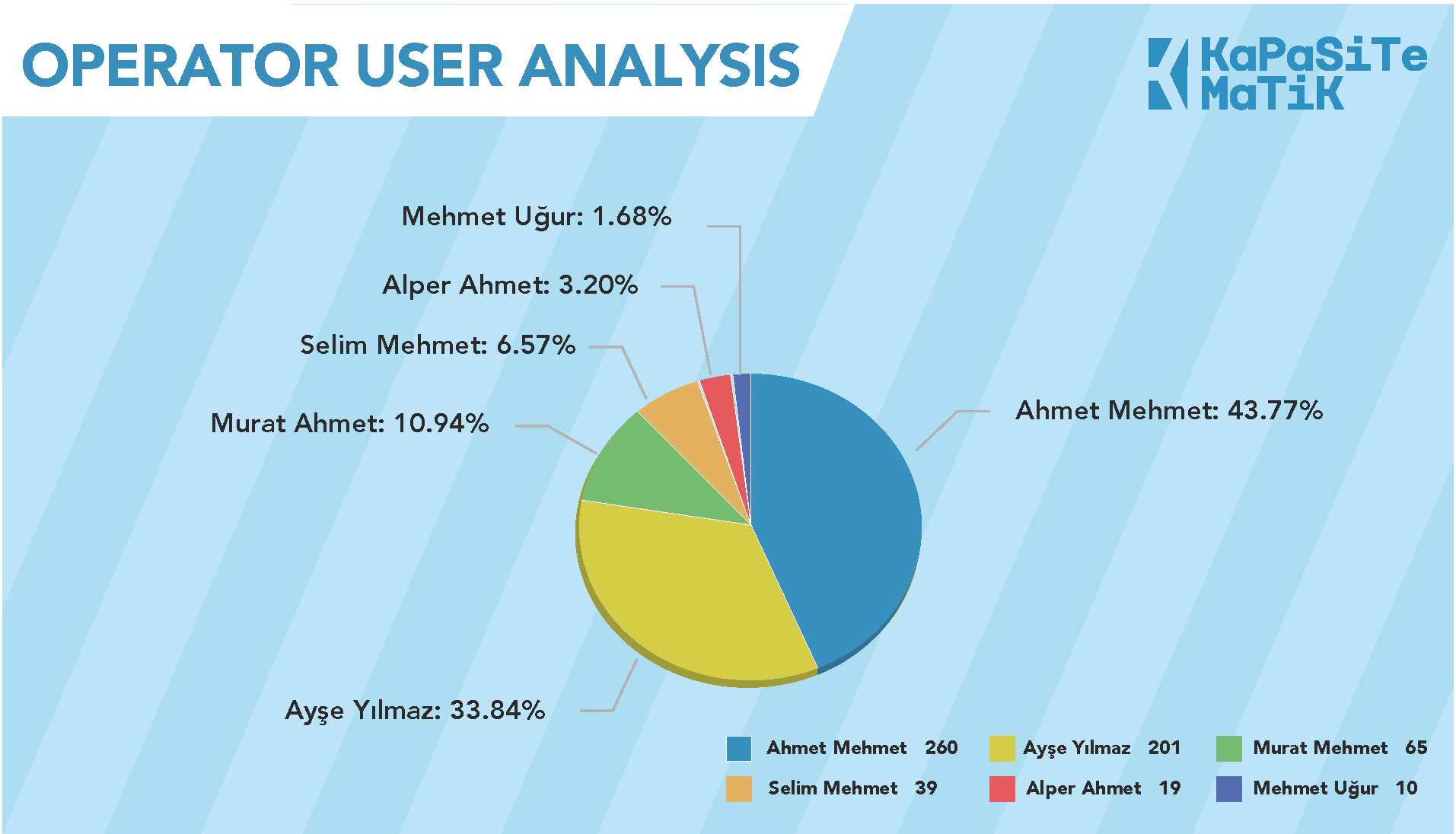

Kapasitematik is a CNC production, tracking and efficiency software developed by "Tezmaksan Makina R&D team". This excellent system, which analyzes machine efficiency instantly with international standard measurements, also enables companies to reduce production costs by reporting error-free production solutions with remote access in line with Industry 4.0.