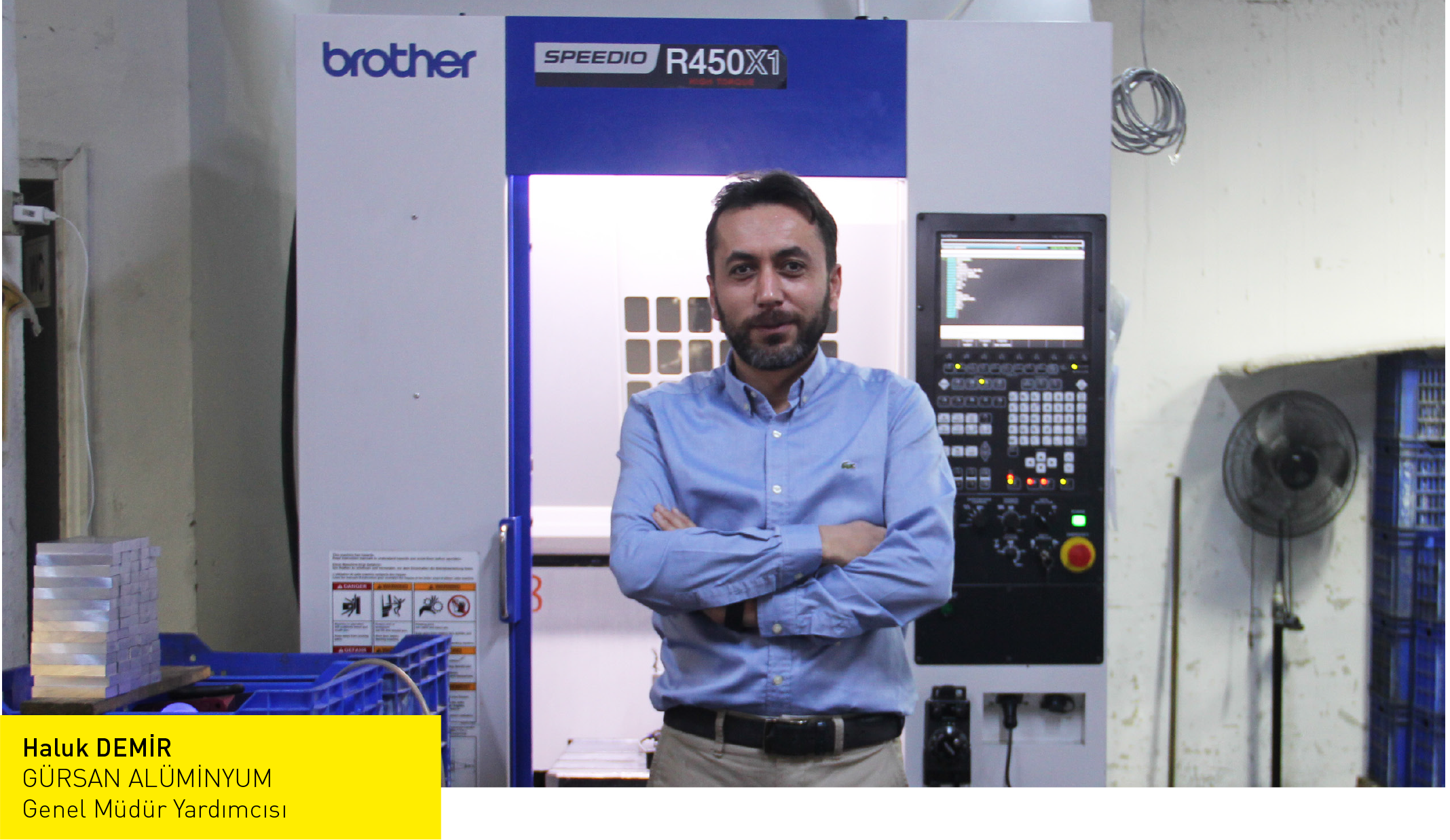

Gürsan Alüminyum: “Our productivity has i ncreased, our shifts have decreased thanks to Capacitymatik” Gürsan Alüminyum, Deputy General Manager Haluk DEMİR: “It was impossible to keep track of issues such as personnel performance, the number and duration of machine part replacements, broken machine tips and changes, before Kalitematik. ”

Gürsan Alüminyum: “Our productivity has i ncreased, our shifts have decreased thanks to Capacitymatik” Gürsan Alüminyum, Deputy General Manager Haluk DEMİR: “It was impossible to keep track of issues such as personnel performance, the number and duration of machine part replacements, broken machine tips and changes, before Kalitematik. ”When did you start collaborating with Tekmaksan?

We have known Tezmaksan since the first day we thought about buying a CNC machine, and we have been following it. Tezmaksan is one of the veteran companies in its field. I can say that we have been collaborating for four years. We have 19 CNC machines, lathes and robot-loaded machines in our organization. During our cooperation process that started with Brother machines, we met with Kabinmatik.

Why do you need Capacitancematik?

We had a lot of question marks about whether we were using the machines efficiently or not. It was almost impossible to keep track of issues such as personnel tracking, machine part replacement numbers and times, broken machine tips and changes. When I calculated that my machine, which I thought was working for 8 hours, worked for an average of 3 hours a day, we needed a system that would record and report all these details. It is necessary to be able to produce added value after machinery investments made with high budgets, and efficient use of machinery is very important at this point. Capacitivematik responds to this need. Thanks to Capacitancematik, I can follow all the personnel, how long each machine works, their unplanned stops and part changes.

How much has your productivity increased after Capacitancematik?

I can't say that it is entirely due to Capacitymatik, but we used to work in double shifts before, now we only produce during the day because we work efficiently. We started to apply a bonus system to our personnel after Capacitancematik, I must say that it is encouraging.

Why did you choose Brother machines?

We know that Brother machines are very fast, high precision and long lasting. The number of parts produced is quite higher than other machines. The fact that Tezmaksan always answered us when service was required was another important reason for our preference.

GÜRSAN ALUMINUM

Establishment Year:1979

Service Area: Aluminum

Supplier of: Aluminum Railing Systems, Tables and Chairs, Waiting Groups (Benches), Door Handles, Solar Energy Support Systems, Aluminum Pergola Systems, Aluminum Garden Fence Systems, Cabin and Glass Partition Systems, Special Productions

Cooperation Area with Tezmaksan: Capacitymatik, Brother, Maintenance and Service